API6D DBB Plug Valve

Design standard :API 6D

Product scope :

1.Pressure scope :CLASS 150Lb~900Lb

2.Nominal diameter : NPS 2~36″

3.Body material:A105、LF2、F304、F316、F304L、F316L、F51,WCB、LCB、WCC、CF8、CF8M、CF3、CF3M、A890 4A etc

4.End connection :RF RTJ BW

5.Drive device: Lever, Gear box, Electric, Pneumatic, hydraulic device, Pneumatic-hydraulic device;

STRUCTURE OF DOUBLE BLOCK & BLEED VALVE

The basic structure of the double block and bleed valve mainly consists of the following two parts

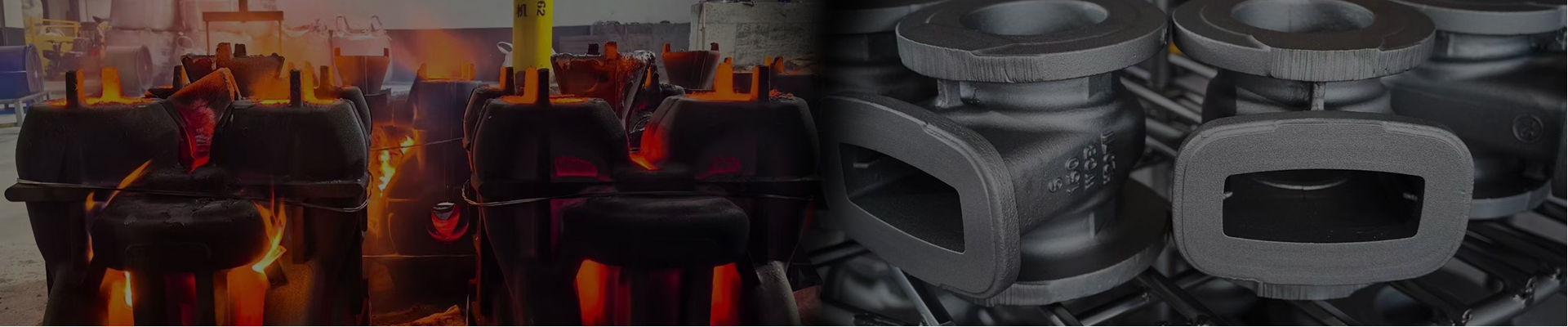

VALVE BODY

The valve body includes such main parts as body, spool, discs (embedded with main gasket ring), end caps, chassis, packing, etc. The spool and the discs are the core of the body part. The spool is fixed inside the body with upper and lower trunnions, with the flow channel mouth in the middle and the wedge faces on both sides.The wedge faces are milled with dovetail guide which is connected to two discs on both sides. The discs are the main sealing element and have cylindrical surfaces.Which can reach a precision up to the B class hard seal. The cylindrical surfaces are milled with a groove circle, into which a main gasket ringffluorinated rubber or nitile rubber, etc,] is permanently embedded with the molding vulcanization method, contributing to hard and soft sealing when the valve is closed.

MANIPULATOR

The manipulator mainly consists of indication sign, handwheel, main shaft bushing, ball pin, bracket and other components, and is fixed on the end cap and connected to the spool bar with a connecting pin. The manipulator part is an actuator for actions. To close the valve from the open position, turn the handwheel clockwise, and the spool will rotate by 90° first to drive the disc to turn to the position of the flow channel mouth of the valve body. Then the spool will move straight downwards to drive the disc to expand radially and get close to the inner wall of the valve body until the soft seal is pressed into the groove so that the disc surface contacts the inner wall of the valve body to complete the closing process.

To open the valve from the closed position, turn the handwheel counterclockwise, and the spool will move straight upwards first, and after it reaches to a certain position, it will rotate by 90° so that the valve can be in a conducting state.