Gas Direct Buried Fully Welded Ball Valve

Ball valve with manual drive with ends for welding for underground installation

PE Directly buried fully welded ball valve Product Range:

Gas buried full welded ball valves are mainly used for city gas: gas output trunk line and various branch supply pipelines, large heating equipment trunk line, branch line, pipeline output pipeline and various circuits open and close, a variety of fluid pipelines, waste gas pipelines, gas, heat, fuel supply pipelines, a variety of heat treatment pipelines, a variety of industrial pipelines and so on.

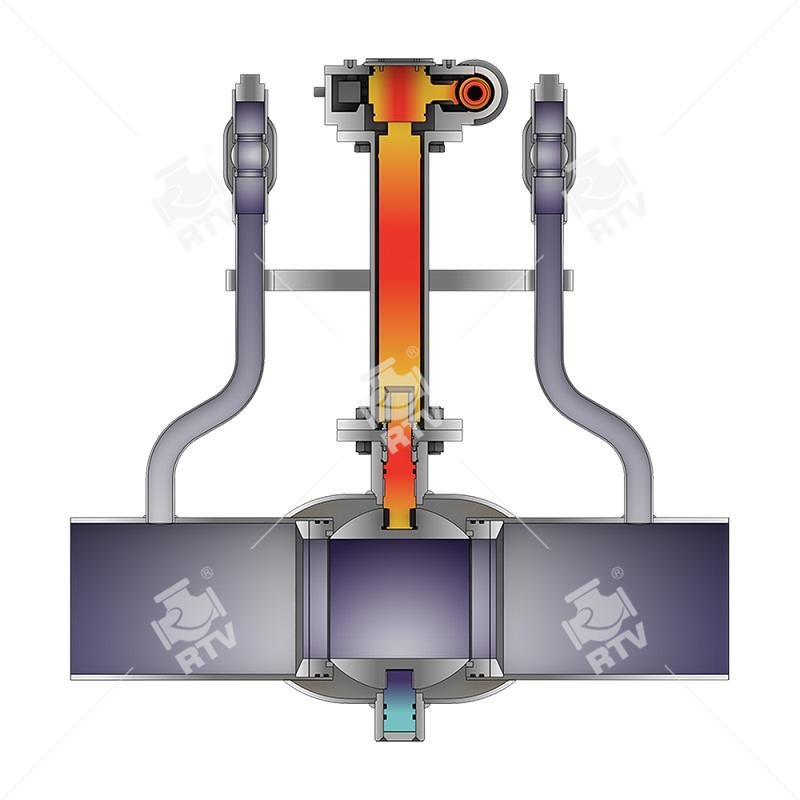

Structural FeaturesAll-welding process structure: the valve adopts all-welding process structure, which improves the internal and external sealing performance of the valve and reduces the leakage risk of the valve, especially in the small Caliber (especially below DN300) reduces the volume of the valve, and the installation is more convenient, which reduces the construction cost and saves time.

Direct buried design, safe and reliable, easy to operate, the operator does not need to enter the ground during transmission operation, avoiding the security risks of entering the ground, only need to use the T handle on the ground for transmission operation, widely used in dense urban traffic and complex gas underground pipelines, natural gas transmission pipelines and regulator stations and other fields.

Structural FeaturesAll-welding process structure: the valve adopts all-welding process structure, which improves the internal and external sealing performance of the valve and reduces the leakage risk of the valve, especially in the small Caliber (especially below DN50-DN2200) reduces the volume of the valve, and the installation is more convenient, which reduces the construction cost and saves time.

Direct buried design, safe and reliable, easy to operate, the operator does not need to enter the ground during transmission operation, avoiding the security risks of entering the ground, only need to use the T handle on the ground for transmission operation, widely used in dense urban traffic and complex gas underground pipelines, natural gas transmission pipelines and regulator stations and other fields.

Size range:2"~32" (DN50~DN800)

Pressure rating:Class 150~300(PN16-PN40)

Connection end:PE end

Operation:Manual,Pneumatic,Electric,Hydraulic

Material: Carbon steel,Low temperature steel,Stainless steel etc.

PE Directly buried fully welded ball valve Design Standards:

Design&manufacture according to GB/T 19627

Face-to-face according to Manufacture standard/on request

End connection according to ASME B16.25

Test&inspection according to GB/T 19627

PE Directly buried fully welded ball valve Features and benefits:

1.Valves are designed with forged steel trunnion mounted.

2.Floating seat.

3.PMSS or metal-metal seat.

4.Balls are fixed by internal mounting plate.

5.Fire safe design as per standard API607/API6FA.

6.Seat structure could be DBB/DIB/DBB-DIB.

7.Weled by typical narrow-gap multi-layer submerged arc welding.

8.Welding seams are inspected by 100% UT and hardness test.

Ball valve with manual drive with ends for welding for underground installation

1: Urban gas: gas output pipelines, main and branch supply pipelines, etc.

2: Centralized heating: Large scale heating equipment output pipelines, main pipelines, and branch pipelines.

3: Heat exchanger: opening and closing of pipelines and various circuits.

4: Steel plant: various fluid pipelines, waste gas selective discharge pipelines, gas and heat supply pipelines, fuel supply pipelines.

5: Various industrial equipment, various heat treatment pipelines, various industrial gas and heat pipelines.

Standard specifications for fully welded ball valves and full bore welded ball valves:

Size: DN50~2200

Pressure rating: PN10-PN160 ,ANSI 150lb~2500lb

Applicable temperature: -35~350 ℃

Valve body material: carbon steel, stainless steel, alloy steel

Internal material: carbon steel, stainless steel, alloy steel, special materials

Features of fully welded ball valve products:

The valve is full bore and has a fixed pivot structure.

The valve seat and valve stem are sealed twice, and the valve seat has an independent grease injection port.

Fixed ball cutoff and release function, equipped with dual piston effect valve seat, zero leakage.

The valve body adopts a fully welded type, which can extend the valve stem and be used underground.

Anti static, fire safe, and valve stem anti blowing function.

Long service life.

It is welded by forged steel. The forging materials are subjected to ultrasonic examination according to ASME nondestructive flaw detection requirements. The welding slope on the connection face is subjected to liquid penetration examination.

Corrosion Resistance And Sulfide Stress Resistance

Certain corrosion allowance is left for the body wall thickness. The carbon steel stem, fixed shaft, ball, seat and seat ring are subjected to chemical nickel plating according to ASTM B733 and B656. In addition, various corrosion resistance materials are available for users to select. According to customer requirements, the valve materials can be selected according to NACE MR 0175/ISO 15156 or NACE MR 0103, and strict quality control and quality inspection should be carried out during the manufacturing so as to fully meet the requirements in the standards and meet the service conditions in sulfurization environment.

Welding Of Transition Pipe

During the manufacturing of the fully welded pipeline ball valve, the transition pipe can e welded for the welding ends valve. The transition pipe can be supplied by users or by our company according to user requirements. Please indicate the transition pipe diameter and length A when placing orders.

Technical Specification

Normal Size Range: 2"-88" DN50 to DN2200

Normal Pressure Rating: ANSI #150 to 900, PN10 Thru PN150

Material: Carbon Steel & Stainless Steel

Optional Locking Device or Stem Extension

Ends Connections: W.ExW.E, W.ExFLG

Optional Direct Mounting to ISO 5211

Full Port or Regular Bore

Double Block and Bleed

NACE MR-01-75

Standards compliance

Design and Manufacture: API 6D, ASME B16.34, EN12516, DIN3357-1

Face to face(end to end): ANSI B16.10,API 6D

Fire-safe: API 607,API 6FA

Butt welded end: ANSI B16.25

Test and inspection: API 598,API 6D