Bi-directional Seal Non-groove Knife Gate Valve

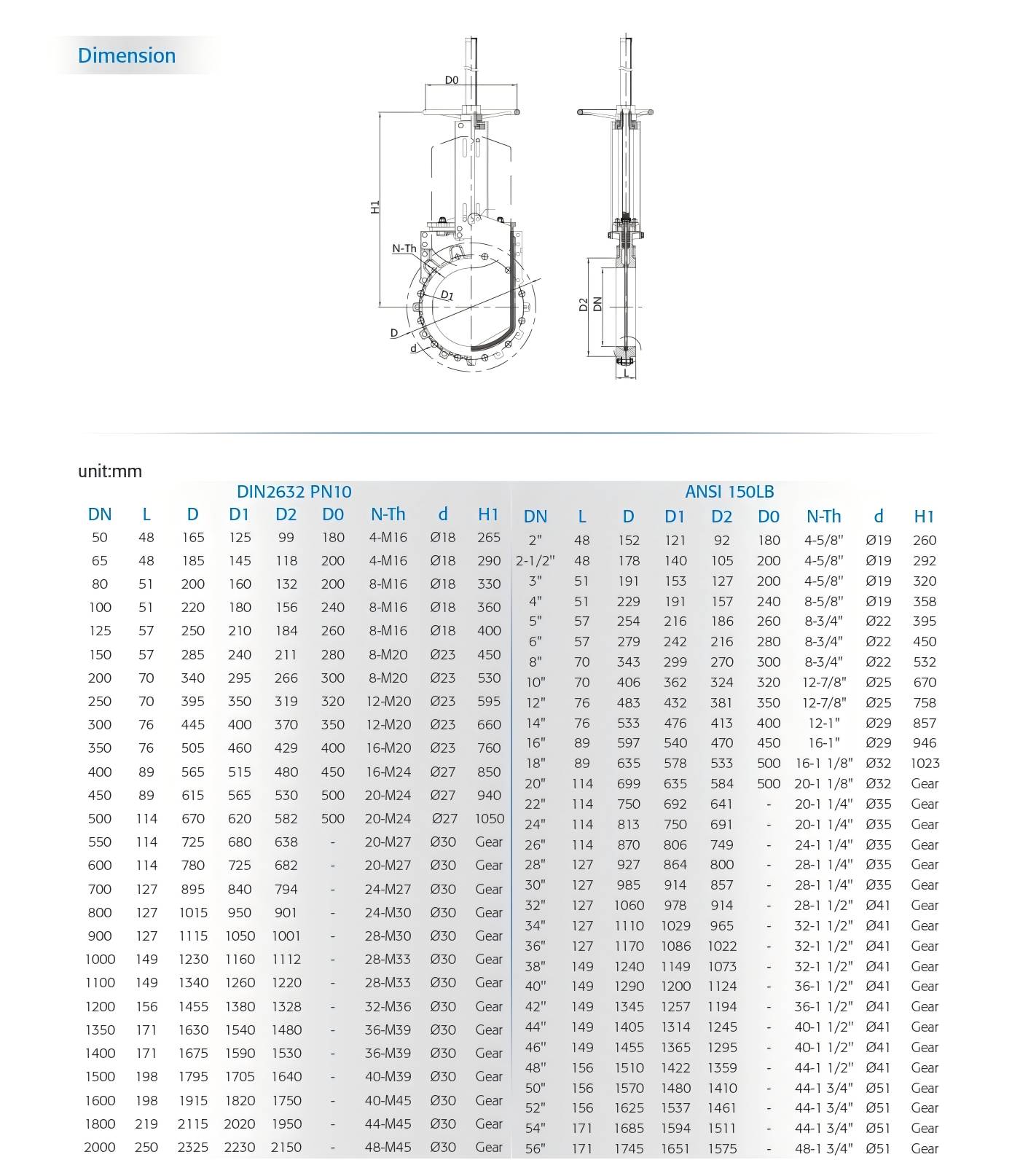

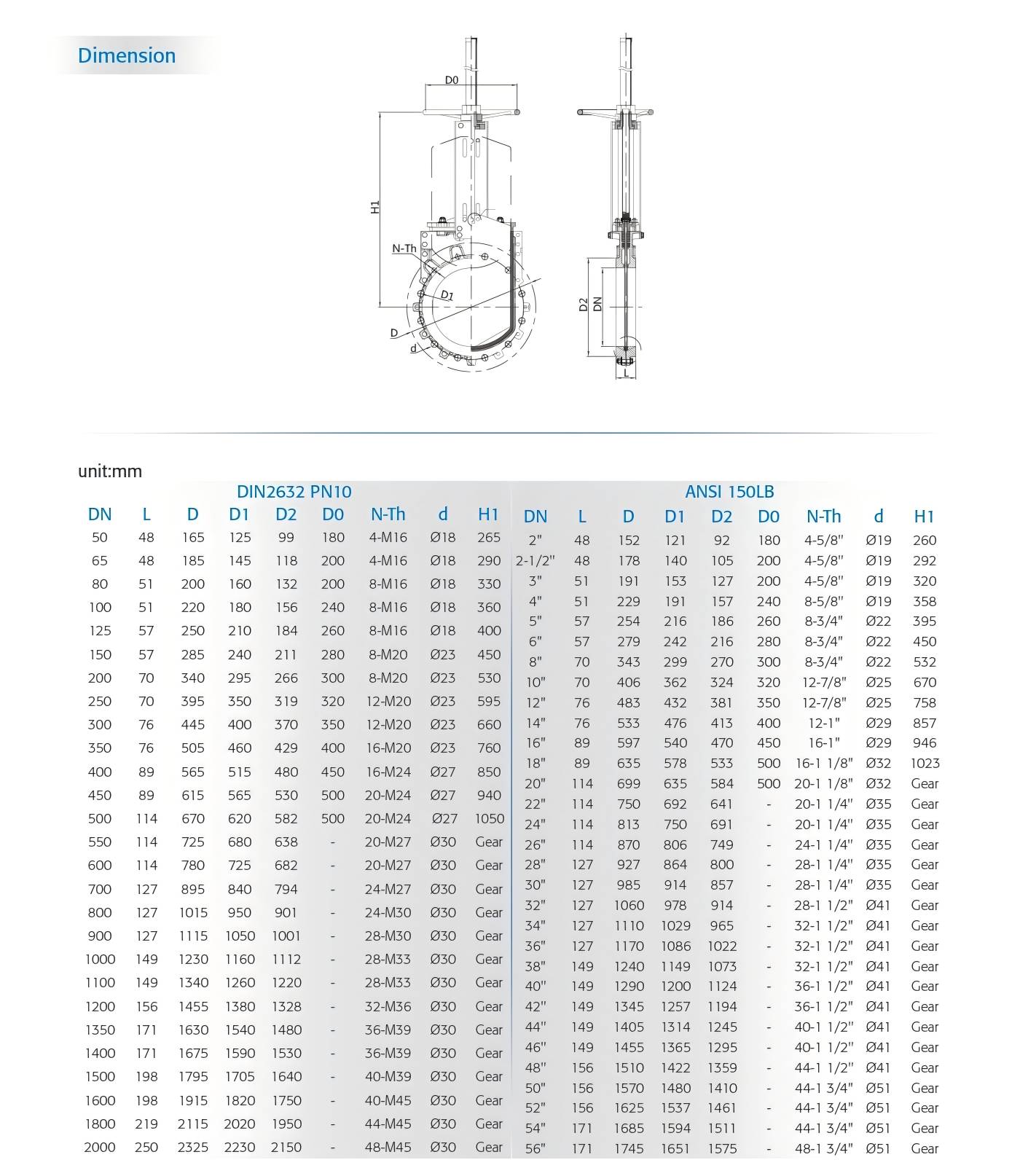

Normal Size Range: 2"-60"

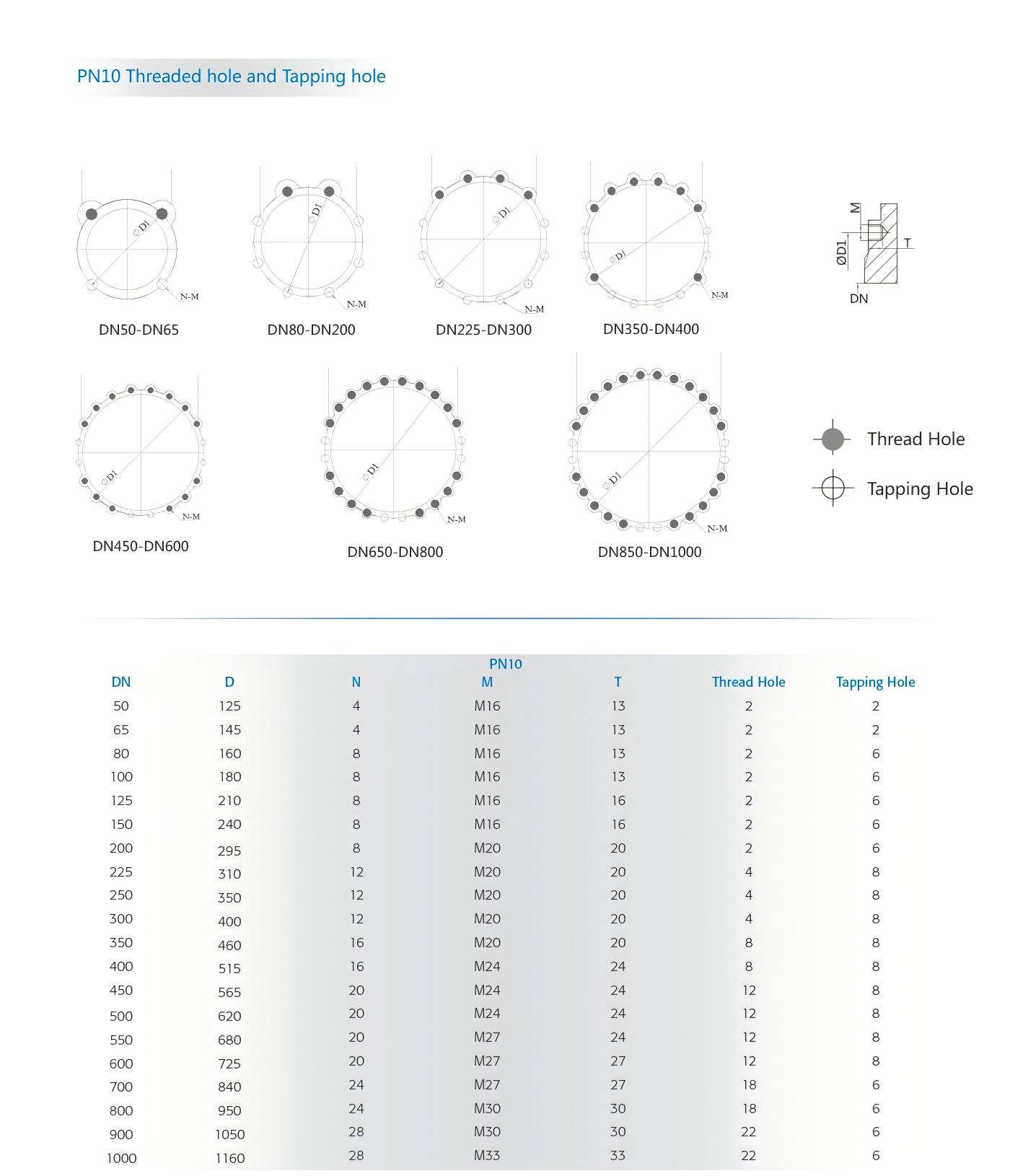

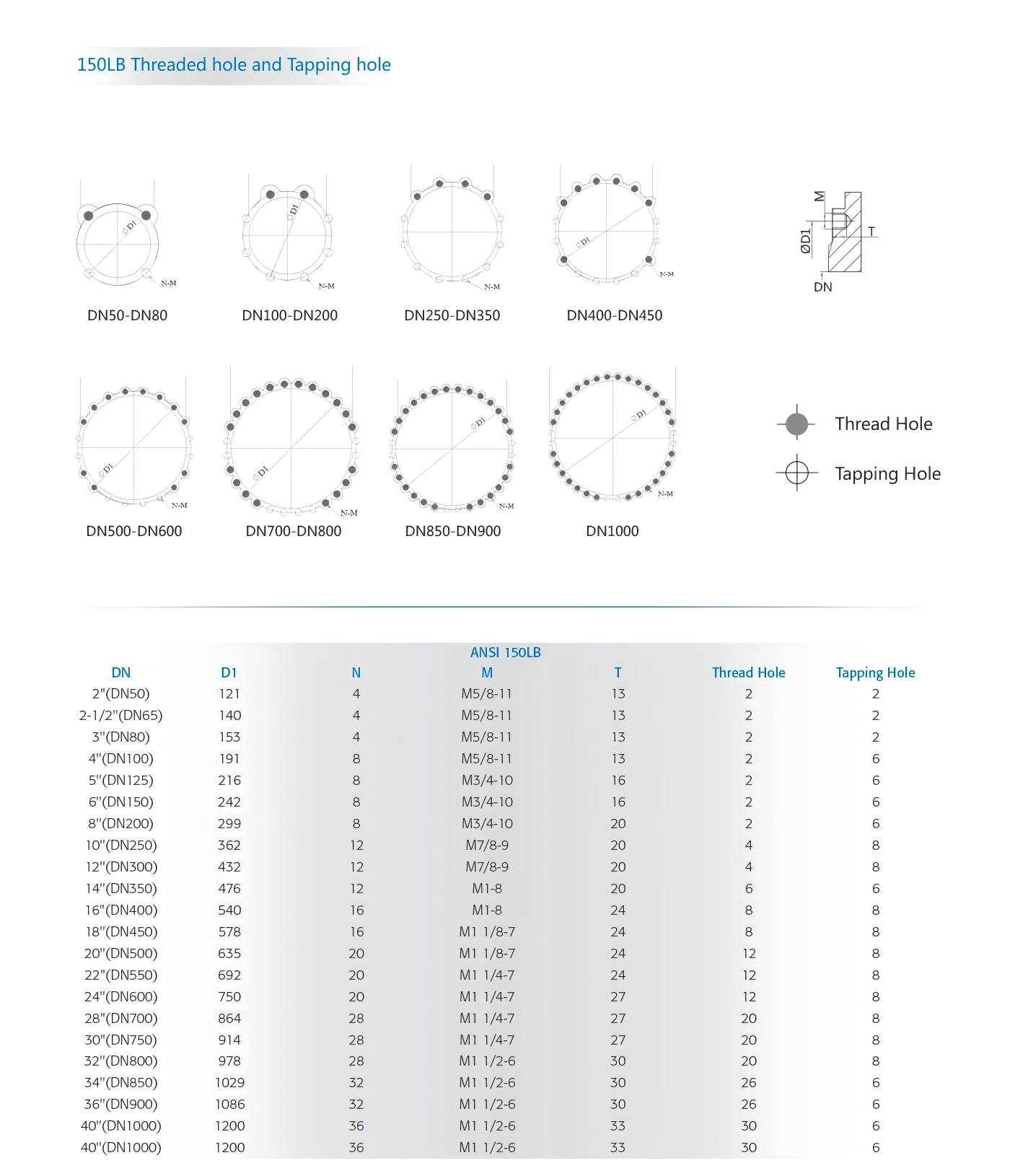

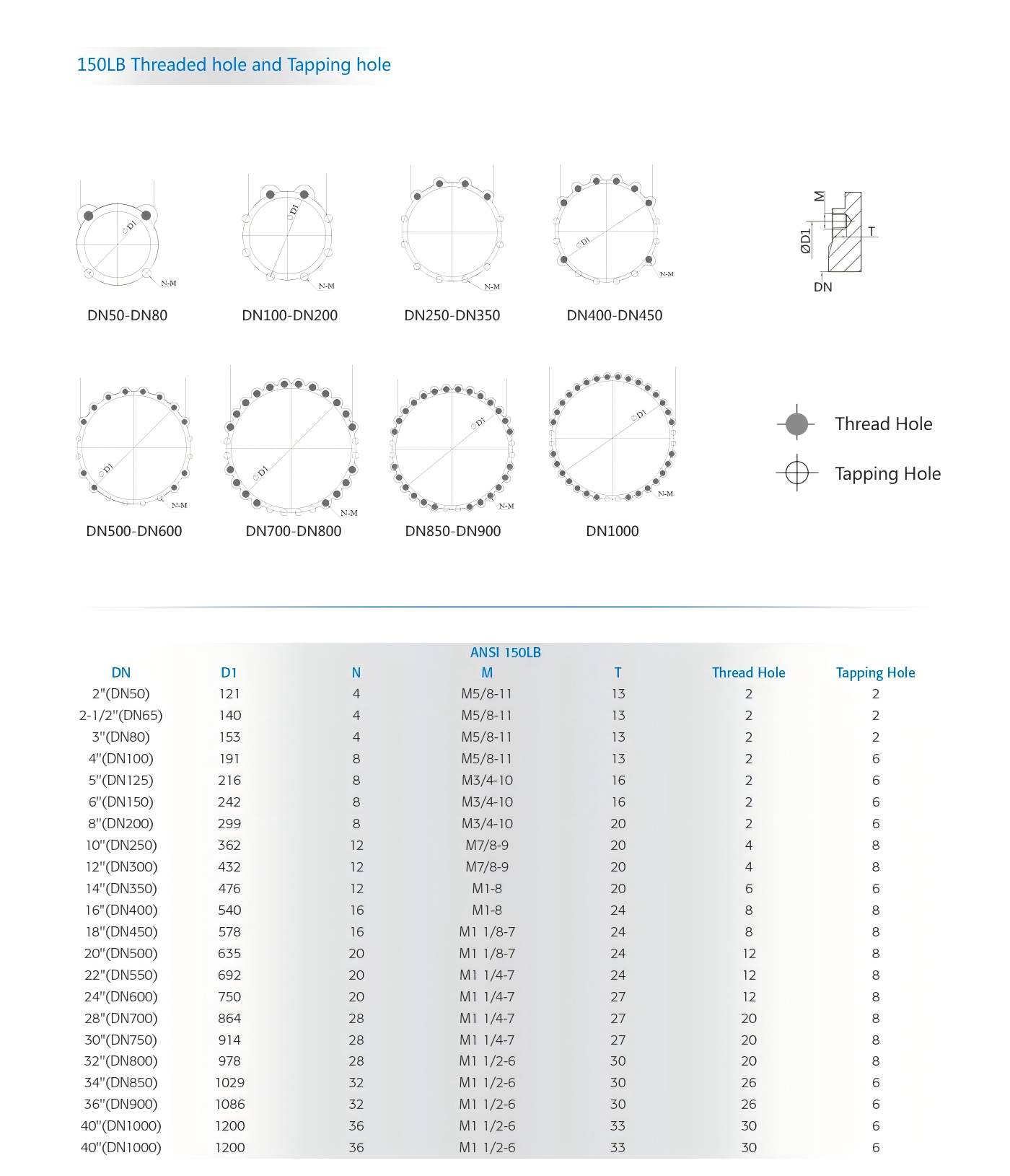

Normal Pressure Rating: PN10~PN16, CLASS150

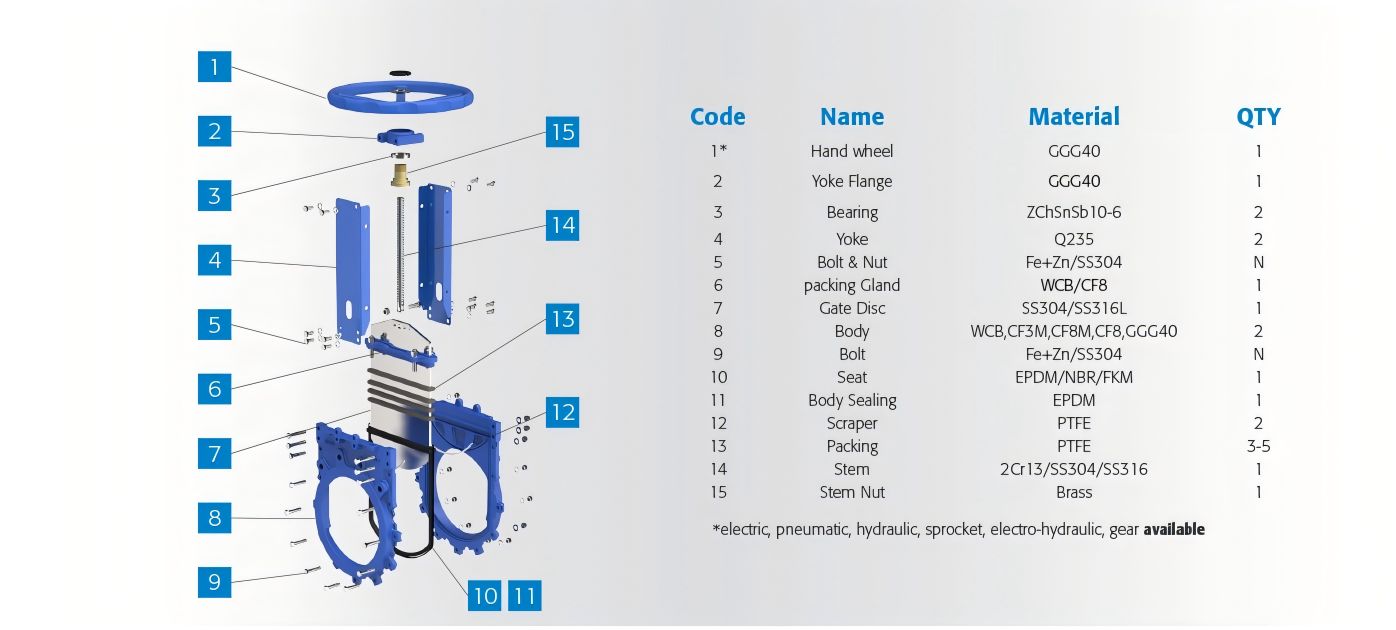

Material: GG25,GG40,WCB, CF8,CF8M,CF3,CF3M

Operation: Handwheel, Pneumatic, Electric, Chainwheel. Lever

Seat: EPDM, Viton, Metal, PTFE, NBR

Temperature Range: -29~150Degree C

Standards compliance

Design and Manufacture: GB/T12237

Face to face(end to end): GB/T15188.2

Flanged connection: ANSI B16.5, GB/T 9113

Test and inspection: API 598, GB/T 13927

RTV Valve QM series slotted bi-directional sealed knife gate valve, cast iron valve body, integral structure knife gate valve, including valve body, gate, and U-shaped flexible seal with groove at the bottom of the valve body. When the valve is closed, the bottom of the gate edge comes into contact with the seal, and then the seal is pressed into the groove in the valve body to achieve the sealing of the gate; When the gate is opened, separate the bottom edge of the gate from the seal, and the seal will bounce back to the same level as the groove. This will prevent the accumulation of medium sediment in the cavity of the groove, without blockage or residue, and the pipeline is easy to clean, effectively improving the sealing effect of the knife gate valve and preventing leakage when the valve is closed.