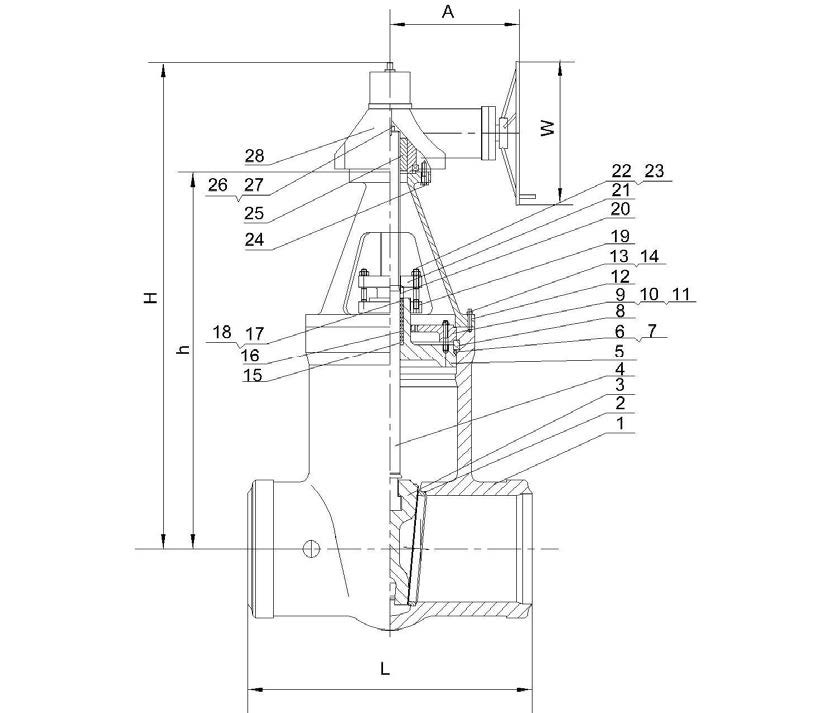

High pressure power station self sealing gate valves produced by RTV Ruitong Valve;

ANSI Pressure Seal Self-tightening Sealing High Pressure Wedge Gate Valve For Power Station.

Specification for Cast Steel Pressure Seal Gate valves

Size Range: 2" thru 24"

Pressure Class: 600-4500

Style: Flexible Wedge and Parallel Slide design

Materials: A216 WCB, WC6, WC9, C5, C12, C12A, CF8M and special alloys

Technical specification

Design & manufacturing standard as per API 600

Face to face standard as per ASME B16.10 / API 6D

Fanged ends standard as per ASME B16.5 / MSS-SP-44/ASME B 16.47/ASME B 16.25

Testing & inspection standard as per API598 / API 6D

Product Range

Body material: Carbon steel, Stainless steel, Alloy steel ,Monel, Duplex, Inconel

Size range(s):1/2"~60"

Pressure rating: Class900~Class 2500

End connection: RF, RTJ, BW

Working temperature: -46℃~ 560℃

Mode of operation: Hand wheel, gear box, Electric , Pneumatic , etc.

Design Features

The valve self-sealing type bonnet.

The disc wedging phenomenon is not liable to be caused when temperature rises.

Flexible wedge.

Full stellite overlay seat sealing surface

Full wedge guiding design.

Absolute bonnet joint leak proof.

Optional by-pass design.

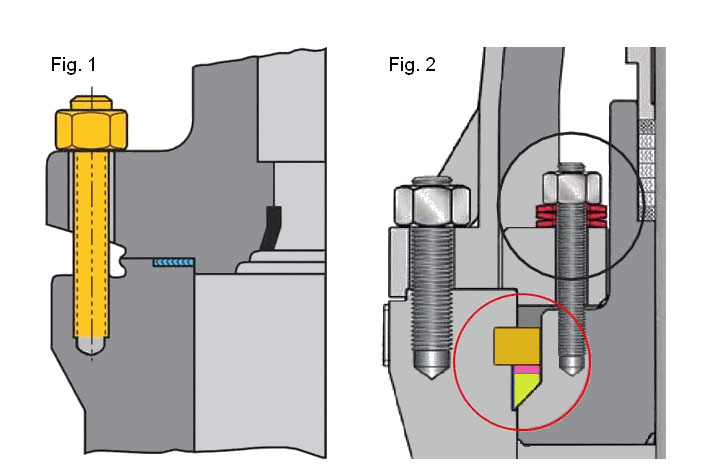

Bolted Bonnets vs. Pressure Seals

The following FIG. 1 depicts the typical Bolted Bonnet valve. The body flange and Bonnet flange are joined by studs and nuts, with a gasket of suitable design/material inserted between the flange faces to facilitate sealing. Studs/nuts/bolts are tightened to prescribed torques in a pattern defined by the manufacturer to affect optimal sealing. However, as system pressure increases, the potential for leakage through the body/Bonnet joint also increases.

The following FIG. 2 Note the differences in the respective body/Bonnet joint configurations. Most pressure seal designs incorporate "Bonnet take-up bolts" to pull the Bonnet up and seal against the pressure seal gasket. This in turn creates a seal between the gasket and the inner dia (I.D.) of the valve body.