2500LB high-pressure shut-off valve cover bolt connection

The Pressure Seal Globe Valves is only suitable for full opening and full closing, and no adjustment and throttling are allowed. The globe valve is a forced seal valve, so when the valve is closed, pressure must be applied to the disc to force the sealing surface not to leak. When the medium enters the valve under the valve, the resistance that the operating force needs to overcome is the friction force of the stem and the filler and the thrust of the pressure from the medium. The force of the valve is larger than that of the valve, so the diameter of the stem is large, otherwise the valve rod will have the failure of the top bending.

Technical Specification

Normal Size Range: 2"-12"

Normal Pressure Rating: PN100~PN420, CLASS600~2500

Material: WCB,LCB,WC6,CF8,CF8M,CF3,CF3M

Temperature Range: -29~425Degree C

Standards compliance

Design and Manufacture: ANSI B16.34,BS1873

Face to face(end to end): ANSI B16.10

Flanged connection: ANSI B16.5

Butt welded end: ANSI B16.25

Test and inspection: API598.

A.Back up ring: Absorbs thrust applied by internal pressure

B.Thrust ring: Protects the soft metallic gasket from deformation

C.Gasket: Unique angular design provides superior sealing

Technical specification

Design & manufacturing standard as per BS1873 /ASME B16.34

Face to face standard as per ASME B16.10

Fanged ends standard as per ASME B16.5

Testing & inspection standard as per API598

Product Range

Body material: Carbon steel, Stainless steel, Alloy steel ,Monel, Duplex, Inconel

Size range(s):1/2"~24"

Pressure rating: Class150~Class 2500

End connection: RF, RTJ, BW

Working temperature:-29℃~ 560℃

Mode of operation: Hand wheel, gear box, Electric-actuator , Pneumatic- actuator, etc.

Design Features

Impactor handwheel for tight shutoff.

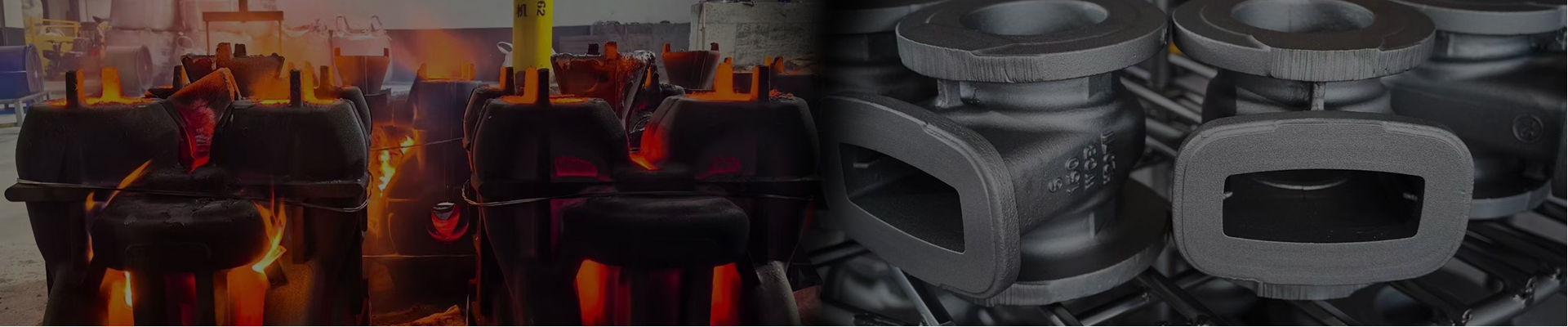

Body made of superior strength forgings and optional cast steel.

Optional live-loading of packing.

Hardfaced seating faces resist erosion.