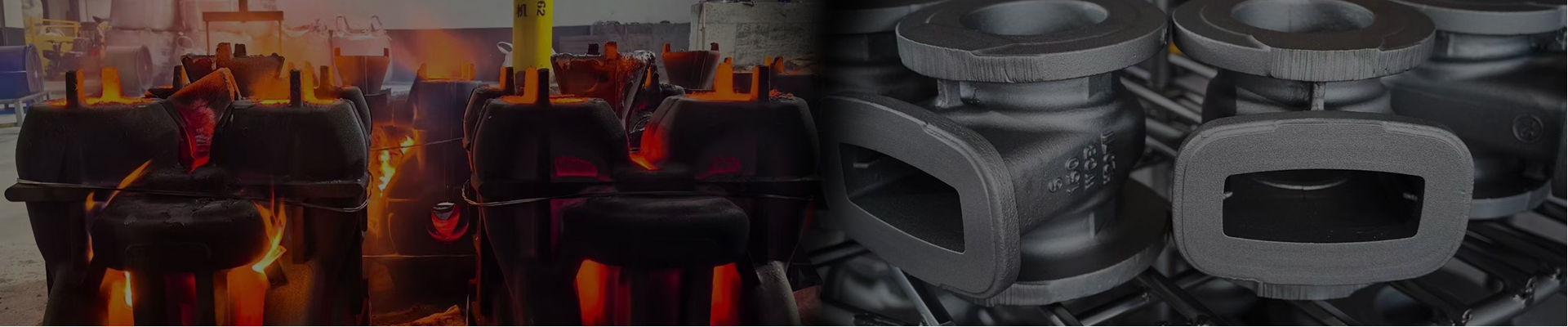

Forged Steel Check Valve

Forged Steel Check Valves in RTV VALVE check, swing check and piton check y-pattern. Forged Check Valves made of high-quality materials.Full or standard port. Bolted or welded cover joint. T-Pattern or Y-Pattern. Integral body seat for piston or ball check. Separate seat ring design for the swing check valve.

RTV Forged Steel Check Valves are available in two bonnet designs. The first design is the Bolted Bonnet, with male-female joint, spiral wound gasket, made in F316L/graphite. Ring joint gasket are also available on request. The second design is the welded bonnet, with a threaded and seal welded joint. On request a full penetration strength welded joint is available.

Ball, piston or swing type disc

T-Pattern or Y-Pattern

Bolted bonnet; welded bonnet; or pressure seal bonnet

Separated seat ring design for swing check valves

Integral Body Seat for Piston and Ball Check valves

Standard

RTV Forged Pressure Seal Swing Check Valves is a valve which is automatically opened and closed by the flow of the medium itself. It is used to prevent the reverse flow of the medium. It is also called the reverse check valve, the one-way valve, the countercurrent valve and the back pressure valve. The check valve is an automatic valve. Its main function is to prevent the backflow of the medium, prevent the reversing of the pump and drive motor, and the discharge of the container medium. The check valve can also be used to supply pipelines where the pressure may exceed the system pressure. Disc check valve around the pin inside the valve seat. The disc check valve is simple in structure and can only be installed on horizontal pipes with good tightness.

Technical Specification

Normal Size Range: 1/2"- 2"

Normal Pressure Rating: PN100~PN420, CLASS600~2500

Material: A105,LF2,F11,F22,F304,F304L,F316,F316L

Temperature Range: -29~425Degree C

Standards compliance

Design and Manufacture: API602

Face to face(end to end): ASME B16.10

Flanged connection: ASME B16.5

Butt welded end: ASME B16.25

Socket-Welding Ends: ASME B16.11

Screwed Ends: ASME B1.20.1

Test and inspection: API598