Structural features:

1. The design and manufacturing of the product comply with advanced foreign standards such as the American national standard ANS1B16.34 and the American BS1873.

2. The valve body has a barrel shaped or streamlined shape that is aesthetically pleasing. The flow shape is straight through. Low fluid resistance.

3. The sealing surface between the closing part (disc) and the valve seat is sealed with a conical surface, which has low closing force, is resistant to erosion, and is reliable in sealing.

4. The valve seat can be a replaceable valve seat, and can be matched with any combination of sealing surface materials to meet the requirements of working conditions and extend its service life.

5. The large-diameter, high-pressure globe valve adopts a lifting rod transmission method for the valve stem according to the needs of closing force, and is equipped with a rolling bearing type and an impact type handwheel to reduce closing force.

6. The materials of the main body, internal components, fillers, and fasteners can be reasonably combined according to user requirements or actual working conditions.

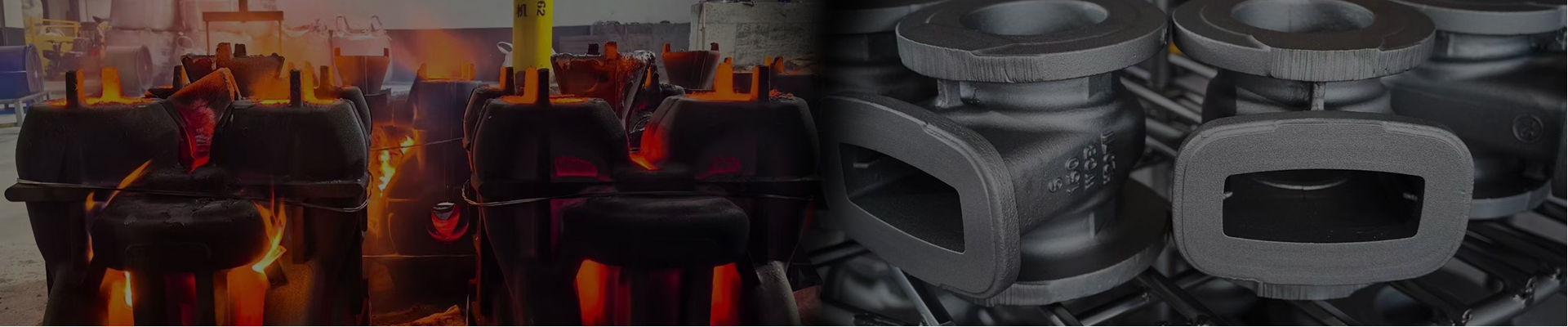

American standard globe valve, ANSI American standard globe valve design standard

RTV Ruitong Valve Co.,Ltd Cast steel globe valves is used for throttling flow control. Shut off is accomplished by moving the disc against the flow stream rather than across it as in the case with a gate valve. The flow pattern through a globe valve involves changes in direction,resulting in greater resistance to flow,causing high pressure drop. RTV Ruitong Valve Co.,Ltd Cast steel Globe valves is an excellent valve to use for on-off service,also is highly suited for frequent cycling and control of fluids anywhere in amount or volume between the open and closed positions.

Technical Specification

Normal Size Range: 4"-24"

Normal Pressure Rating: PN10~PN420, CLASS150~2500

Material: WCB,LCB,WC6,CF8,CF8M,CF3,CF3M

Temperature Range: -29~425Degree C

Standards compliance

Design and Manufacture: ANSI B16.34,BS1873

Face tu face(end tu end): ANSI B16.10

Flanged connection: to ANSI B16.5

Butt welded end: ANSI B16.25

Test and inspection: API598

A.Anti-friction ball thrust bearing: Reduces friction between mating parts to ensure smooth operation

B.Grub screw: Secures yoke nut in the bonnet

C.Grease nipple: Supplies lubricant to the mating parts