Features of flat gate valve products

PN210 Gate valve,PN350 Gate valve,PN700 Gate valve,Py210 gate valve,Py350 Gate valve,Py700 Gate Valve

1. The valve seat adopts an O-ring seal and a floating valve seat structure with pre tightening force applied, which makes the inlet and outlet of the flat gate valve sealed in both directions; And the opening and closing torque of this structure is only half of that of a regular valve, which can easily open and close the valve

2. When fully open, the channel is smooth and straight, with minimal flow resistance coefficient and no pressure loss. It can clean the pipeline with a capillary ball

3. Adopting a packing structure with self sealing ability, without the need for frequent adjustment, the opening and closing are extremely lightweight, and the sealing performance is reliable. There is an auxiliary sealing grease injection structure at the packing box, which is absolutely reliable in sealing performance and truly achieves zero leakage; Solved the problem of leakage at the packing of general valves

4. When the flat gate valve is closed, it can automatically remove the high pressure inside the chamber, ensuring safe use

5. Fully enclosed structure, good protective performance, and can adapt to all-weather requirements

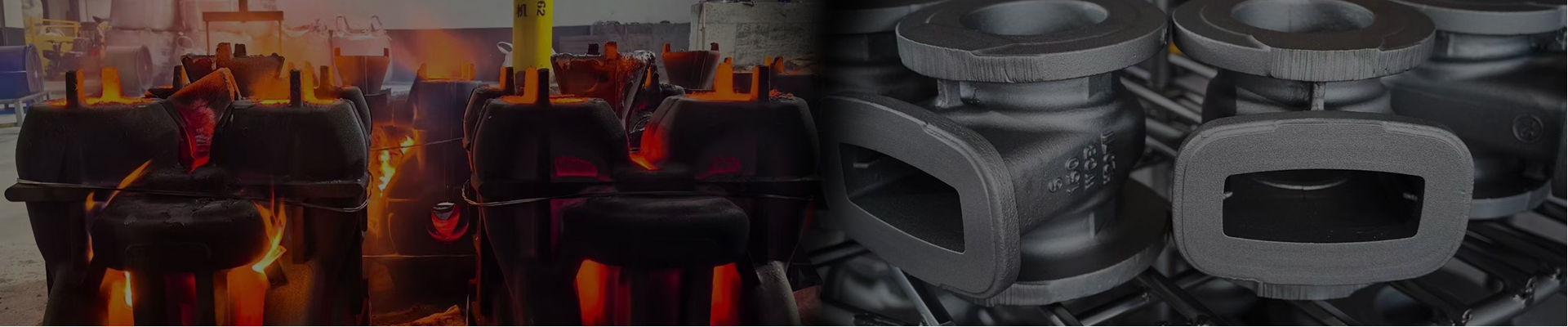

PFFW rising stem flat gate valve is a high-performance, bi-directional sealed concealed stem gate valve. Integral forging forming, with excellent performance in high-pressure environments, can be applied to oilfield wellheads, Christmas trees, gas trees, and manifold systems ranging from 2000psi to 20000psi.

Executive standard for flat gate valves

Nominal caliber: 1-13/16 "~9"

Working pressure: 2000psi~20000psi

Temperature Class: LU

Material grade: AA~FF

Specification level: PSL1~PSL4

Performance level: PR1~PR2

Design Execution Standard: API 6A

API 6A Slab Gate Valve have PFFA Series and PFF series. Details as below:

PFFA Series Gate valve

Full bore design eliminates efficiently pressure drop and vortex, eliminates washing by solids in fluid.

Mental-to-mental seal is used between bonnet and body, gate and seat body and seat

The surface of gate andseat is weld overlay with hard alloy. which has feature of corrosion resistance and washing resistance.

The bonnet and stem designed with back seal, can replace stem sealing under pressure

One side of bonnet is designed with sealant injection in order to supply sealant and improve seal and lubrication performance of gate and seat.

Can complete with different pneumatic (hydraulic) actuator upon user s requirements

Working Pressure: 2000PSI-20000PSI

Nominal Bore: 1-13/16-9"(46mm-230mm)

Working Medium: oil、 natural gas、 mud and gas ,containing has、co

Working Temperature:-46C-121'C(Class LU)

Material Class: AA、BB、cc、DD、EE、FF、HH

Specification level: PSL1-4

Performance Requirement: PR1-2

PFF Series Gate Valve

Full bore design eliminates efficiently pressure drop and vortex eliminates washing by solids in fluid

Mental-to-mental seal is used between bonnet and body, gate and seat, seat and body

The surface of gate and seat is welding overlay with hard alloy, which has feature of

corrosion resistance and washing resistance.

The balanced stem can balance the stem load. Reduce load of stem thread and bearing to decrease operating torque.

The bonnet and stem are designed with back seal, which can replace stem sealing under pressure.

One side of bonnet is designed with sealant injection valve.

Rising stem structure can indicate open and close of valve.

Complete with different pneumatic(hydraulic) actuator upon users requirements.

Working Pressure: 2000PSI--20000PSI

Nominal Bore: 1.13/16-9"(46mm-230mm

Working Medium: oil、 natural gas、 mud and gas, containing H:S、co

Working Temperature: -46C-121C(Class

Material Class: AA、BB、cc、DD、EE、FF、

Specification level: PSL1--4

Performance Requirement: PR1-2

Full port design

Double blocking and discharge

Emergency sealant injection

Single or double reel

Orifice type or non-orifice

Flange or butt welding end

Fire protection design conforms to API 6A

Specifications