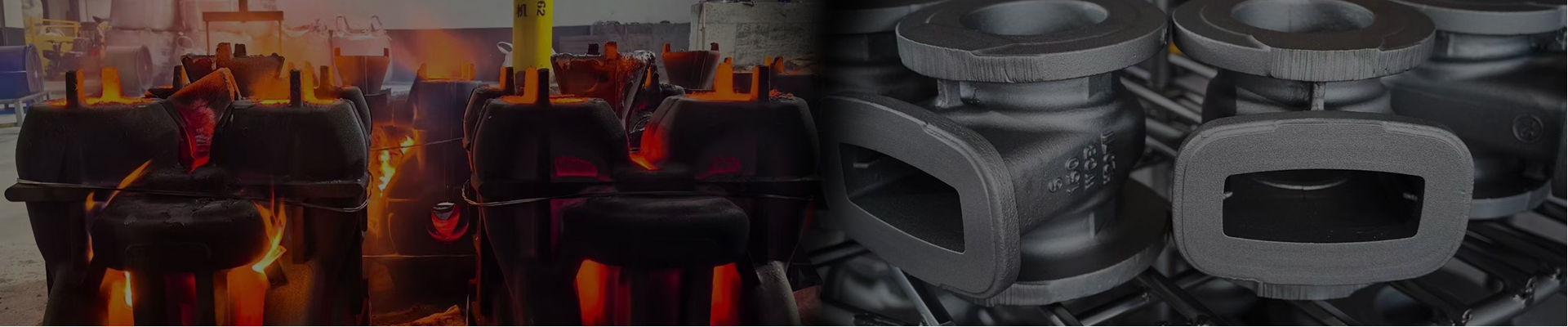

Working principle of forged steel globe valve:

The middle chamber of the forged steel socket welding globe valve adopts a self tightening sealing structure, which has good sealing performance. The two ends of the branch pipe are welded structures. The sealing surfaces of the valve disc and valve seat are made of Stellite cobalt based hard alloy overlay welding, which is wear-resistant, high-temperature resistant, and has good scratch resistance. The valve stem has undergone quenching and surface nitriding treatment. The depth of the valve cover packing box is reasonable, and the packing with corrosion inhibitor is reliable for sealing. The valve has an inverted sealing structure to ensure that there is no leakage from the valve stem during valve opening and operation. Widely used in fields such as petroleum, chemical, natural gas, metallurgy, chemical fiber, papermaking, urban construction, etc.

Features of forged steel globe valves:

1. The product design and manufacturing are in accordance with the ANSIB16.34 and E101 standards, and can be equipped with imported equipment for use.

2. The inner chamber of the valve adopts a pressure self tightening sealing structure, and the higher the inner chamber pressure, the better the sealing performance.

3. The sealing surfaces of the valve disc and valve seat are made of Stellite cobalt based hard alloy overlay welding.

4. The depth of the valve cover packing box is reasonable, the packing is added with corrosion inhibitor, the sealing is reliable, and the switch is stable.

5. The valve has an upper sealing structure to ensure that there is no leakage from the valve stem during valve opening and operation.

Design specification: Steel forged globe valves shall be manufactured in accordance with API602, BS5352,ANSI/ASME B16.34, Testing and acceptance shall be in accordance with API 598, and identification shall be in accordance with MSS SP-25.

When the Self Sealing Forged Steel Globe Valve is opened, the opening height of the disc is 25% to 30% of the nominal diameter, and the flow rate has reached the maximum, indicating that the valve has reached the full open position. Therefore, the full opening position of the globe valve shall be determined by the stroke of the disc. Valves of this type should be installed horizontally in pipes. The globe valve has the adv

antages of simple structure, convenient manufacture and maintenance, small working stroke, short opening and closing time, good sealing performance, small friction force between the sealing surfaces and long service life.

Technical Specification

Normal Size Range: 1/2"- 2"

Normal Pressure Rating: PN100~PN420, CLASS600~2500

Material: A105,LF2,F11,F22,F304,F304L,F316,F316L

Temperature Range: -29°C~425°C

Standards compliance

Design and Manufacture: API602

Face to face(end to end): ASME B16.10

Flanged connection: ASME B16.5

Butt welded end: ASME B16.25

Socket-Welding Ends: ASME B16.11

Screwed Ends: ASME B1.20.1

Test and inspection: API598