Product features

1. There are two and four sealing structures, and the valve core hole has two structural forms: L-shaped and T-shaped. By controlling the rotation angle of the valve core and changing the connection status between the valve core hole and the pipeline mouth, it can achieve different combination control of the three branch pipes. The three-way ball valve has a large flow capacity and can control gases, liquids, and vapors, making it more suitable for controlling high viscosity, fibrous and granular fluids. It is also suitable for occasions with strict sealing requirements.

2. The two seat sealed three-way ball valve has a compact structure, beautiful appearance, and good sealing performance, which can achieve the switching of medium flow direction in the pipeline. It can also connect or close two perpendicular channels.

3. The four seat sealed three-way ball valve has a beautiful appearance and a compact and reasonable structure. It can not only switch the flow direction of the medium, but also connect the three channels. At the same time, any channel can be closed to connect the other two channels, and the pipeline can be flexibly controlled to merge or separate the medium.

4. The T-shaped valve core hole can connect or switch three orthogonal pipelines to each other, playing a role in diversion or convergence; L-shaped channels connect two pipes that are orthogonal to each other. Cut off another channel to change the flow direction of the medium.

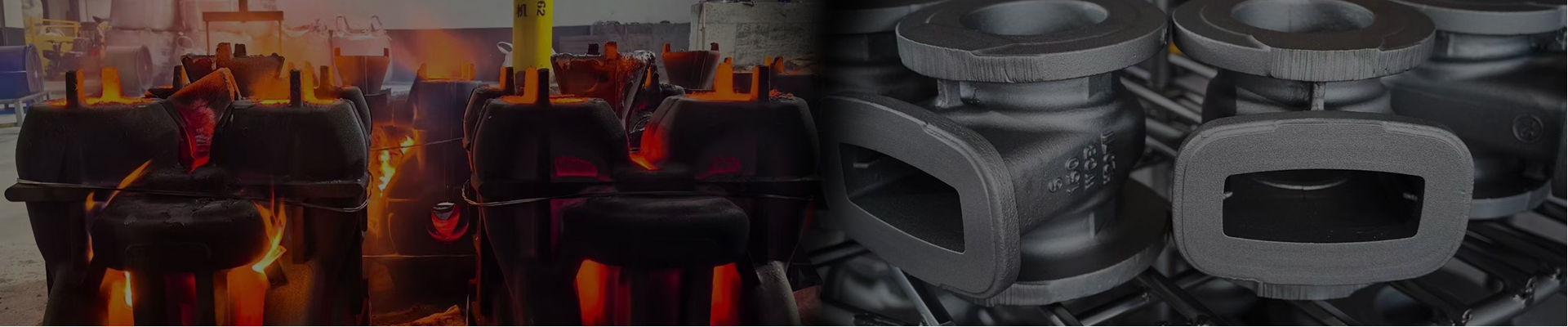

5. The electric three-way ball valve is suitable for switching the flow direction of media and diverting or mixing fluids in pipeline systems such as water supply, petrochemical, metallurgical, mining, light textile, energy, papermaking, food, steel, etc.

Characteristics of electric three-way ball valve:

1. Compact structure, fast opening and closing, unobstructed flow channel, and low fluid resistance.

2. Good sealing performance: Utilizing PTFE elastic deformation of the four sided valve seat material to achieve leak free sealing.

3. One valve for multiple purposes: Any port can be used as an inlet without leakage, and the three-way can be made into an L-shaped port or a T-shaped port.

4. Easy maintenance: After the system is depressurized, the entire valve body can be inspected and repaired without the need to remove it.