Structural characteristics of pneumatic shut-off valves

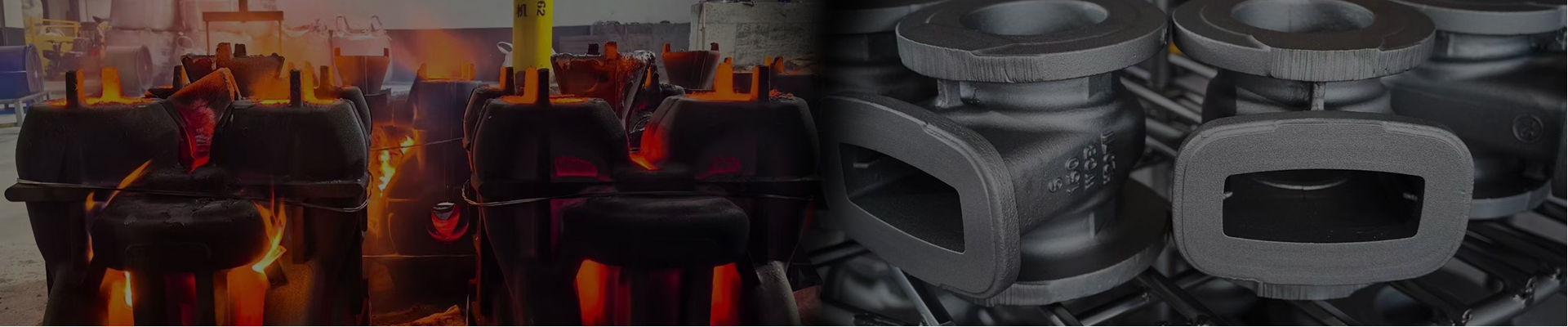

Carefully selected materials, in compliance with relevant domestic and international standards, with a reasonable structure and beautiful appearance.

The sealing surfaces of the valve disc and valve seat are made of iron-based alloy overlay welding or Stellite cobalt based hard alloy overlay welding, which has good wear resistance, high temperature resistance, corrosion resistance, scratch resistance, and long service life.

The valve stem has undergone quenching and surface nitriding treatment, which has good corrosion resistance and scratch resistance.

Various piping flange standards and flange sealing surface types can be used to meet various engineering needs and user requirements.

The valve body material variety is complete, and the packing and gasket can be reasonably selected according to actual working conditions or user requirements, which can be suitable for various pressure, temperature, and medium working conditions.

The reverse seal is made by connecting the sealing seat with threads or welding austenitic stainless steel on the body, which is reliable in sealing. The replacement of fillers can be carried out without stopping the machine, which is convenient and fast, and does not affect the operation of the system.

The working principle of most valves that use compressed air as the power source is remote control, which is manually or automatically triggered by the main control room to activate the intake and exhaust solenoid valves and supply and exhaust compressed air to the actuator. Compressed air acts on the piston or diaphragm, overcoming the frictional force of valve action and the spring force on the valve stem, thereby pressing down (for valve opening due to loss of air) or lifting up (for valve closing due to loss of air) the valve stem, driving the valve core to move up and down, causing the valve to open or close.

Product features

1. The double acting cylinder is easy to operate and flexible.

2. The sealing surface adopts conical sealing, with low closing force, erosion resistance, and reliable sealing.

3. The valve stem has undergone quenching and surface nitriding treatment, which has good corrosion resistance and scratch resistance.

4. The valve body material variety is complete, and the packing and gasket can be reasonably selected according to actual working conditions or user requirements, which can be suitable for various pressure, temperature, and medium working conditions.

5. Design and Manufacturing: GB12237-89 API608、API 6D、JPI 7S-48、BS5351、DIN3357.

6. Flange size: JB/T74-90 (JB74-90) GB9112~9131、HGJ44~76、SH3406、ANSI B16.5、JIS B2212~2214、NF E29-211、DIN2543.

7. Structural length: GB12221-89 ANSI B16.10、JIS B2002、NF E29-305、DIN3202.

8. Inspection main test: JB/T 9092, API 598.